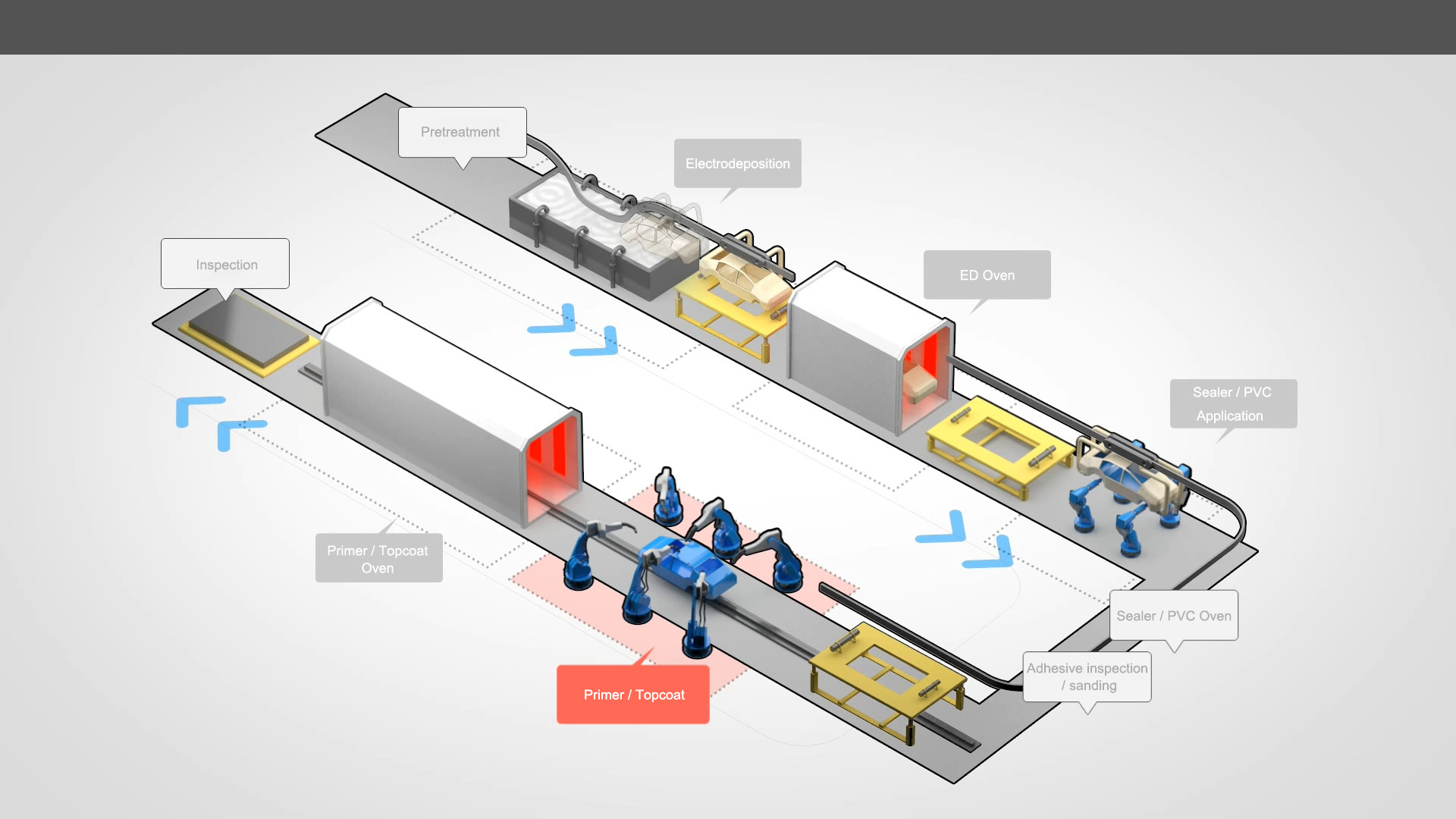

1. Ukwelashwa Ngaphambili: Ukuze kukhishwe uwoyela ongadingekile, izinsalela zokushisela, nokungcola ebusweni bokufakwa komzimba wemoto embonini yomzimba, ifilimu ye-zinc phosphate (3~5㎛) isetshenziswa ebusweni bomzimba ukuze kwandiswe ukunamathela ngesikhathi se-undercoating (i-electrodeposition). inqubo. Ngenhloso yokuvikela ukugqwala komzimba wemoto.

- Ngaphambi kokuhlanza: Ngemva kokuhlanganisa umzimba, ugezwa ngamanzi ngaphambi kokuwususa amafutha.

- Main degreasing: Kususa amafutha emzimbeni wemoto.

- Ukugeza okunemibandela: I-ejenti yokwelapha ene-titanium njengengxenye eyinhloko, edala inani elikhulu lama-colloid endaweni yensimbi ukuze kwandiswe ukusebenza kabusha kokwenza ifilimu eliminyene le-zinc phosphate ukukhiqiza amakristalu amahle naminyene.

- Ifilimu ye-Zinc phosphate: Ifilimu ye-zinc phosphate isetshenziswa ukuqinisa ukunamathela kwe-undercoat futhi ivimbele ukusabela kokugqwala.

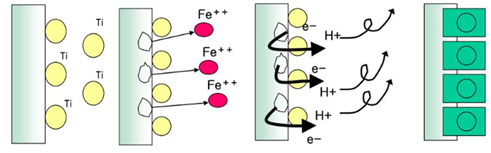

1) I-Etching iqala engxenyeni ye-anode yeshidi lensimbi kusixazululo sokumboza

2) Ngokuya ngokugqwala kwamanje, ama-cations asetshenziswa ku-cathode, futhi i-pH yesixhumi esibonakalayo iyakhuphuka.

3) I-Colloid ebusweni iba yi-nucleus futhi icwebezela

- Ihhavini elomile lamanzi: Inqubo yokususa ngokuphelele umswakama ku-substrate ngemva kokuphothulwa kwenqubo yangaphambi kokwelashwa.

※ Ukudlulisa ukushisa nokomisa ekomisweni kwesandla

Ngemva kokumboza umzimba ngefilimu ye-zinc phosphate (), yigeze ngamanzi bese uyomisa ngesandla. Ukomiswa ngesandla kuyinqubo yokususa ngokuphelele umswakama entweni ezogcotshwa bese wenza inqubo yokudweba elandelayo. Phakamisa izinga lokushisa ukuze uhwamuke umswakama ngokudluliswa kokushisa. Ukomisa (ukuhwamuka) kuyisenzakalo esenzeka lapho izinga lokushisa lendawo eqinile lapho kuthintana khona liphansi kunendawo yokubilisa kanye nomfutho womoya womkhathi uphansi kunokucindezela komhwamuko. ushintsho lwesigaba luzokwenzeka. Izinga lokushisa nesikhathi esidingekayo ukuze isithando somlilo esisika ngesandla siyehluka kuye ngempahla, ukujiya, kanye nokuma kwento ezogcotshwa. Ngokuvamile, imizuzu eyi-10 ku-120 ~ 150℃ ivamile, futhi isizathu sokukhulisa izinga lokushisa ukukhulisa umfutho we-vapor wamanzi ohambisana nalelo zinga lokushisa kanye nokoma ngokushesha ngokunikeza amandla okushisa engeziwe. Ngalesi sikhathi, akufanele kube noshintsho lwensimbi noma lwamakhemikhali ngenxa yezinga lokushisa.

1,Inqubo ye-Electrodeposition: Inqubo yokwenza ifilimu yokuhlanganisa ngaphakathi/ngaphandle komzimba wemoto ngokusebenzisa i-electrophoresis ngogesi ngemva kokucwilisa umzimba wemoto kupende we-electrodeposition, ngenjongo yokuvimbela ukugqwala komzimba wemoto.

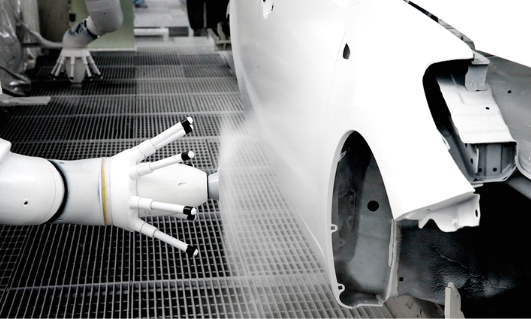

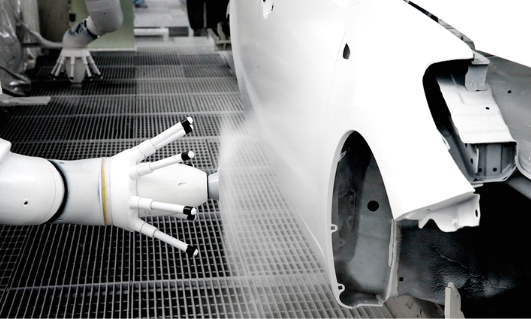

- I-Electrodeposition: Umdwebo we-Electrodeposition yinqubo yokudweba lapho upende unamathiselwe khona ngogesi ngokucwilisa umzimba wemoto esixazululweni sikapende kanye ne-anode egelezayo noma i-cathode emzimbeni wemoto. Kodwa-ke, kuyindlela efanelekile yokukhiqiza ngobuningi, futhi kunzima ukuyipenda kabusha uma ifilimu yokumboza isinamathiselwe futhi ugesi ungagelezi.

- DI geza

- I-Electrodeposition Drying Furnace: Ezembozweni ze-cationic electrodeposition, ezisetshenziswa kakhulu, isithando somlilo esomisa ukushisa sisetshenziswa ngoba ifilimu efakwe phezulu yenziwa bushelelezi yi-thermal fluidization ngokusabela kwe-thermal crosslinking (i-thermal curing). Izinga lokushisa kanye nesikhathi esidingekayo ukuze kulungiswe ukushisa kuyahlukahluka kuye ngempahla, ukujiya, kanye nokuma kwento ezogcotshwa. Endabeni yento eboshwe ngokuqhathaniswa izacile, izinga lokushisa elingaphezulu lingama-200-210 ° C kanti izinga lokushisa lomlilo liba ngu-210-230 ° C, futhi isikhathi sokushisisa ngokuvamile siyimizuzu engu-20-30 isiyonke imizuzu eyi-10 noma ngaphezulu ngesikhathi sokushisisa sento ezogqunywa kanye nesikhathi sokubamba esingu-200-210 ° C.

- Ukupholishwa kwe-Electrodeposition: Gaya izingxenye ezimahhadlahhadla neziphumela ngaphandle ukuze zibushelelezi.

2, I-Halfway Paint: Lena inqubo yokufaka upende, okuvame ukubizwa ngokuthi i-primer. Ihlanza indawo engaphezulu ukuze ijazi eliphezulu linamathele kahle futhi libambe iqhaza ekuthuthukiseni ukumelana nokugqwala. Ngisebenzisa umbala ohluke kancane womaphakathi ukuze uhambisane nombala wejazi eliphezulu.

- Inqubo Intermediate

- Isithando somlilo esiphakathi

3, ijazi eliphezulu: Inqubo yokufaka umbala wemoto obonakalayo nokuqeda ngopende osobala. Muva nje, ngenxa yemithetho yezemvelo, njll., amapende e-eco-friendly (okuqukethwe okuphansi kwezinto eziguquguqukayo) asetshenziswa kancane kancane. Sula ngemva kwejazi eliphezulu

- inqubo yejazi eliphezulu

- Isithando somlilo se-Topcoat

※ Ukudlulisa ukushisa ku-electrodeposition/maphakathi/top coat heat and drying dace

Esithandweni somisa, ukushisa kudluliselwa endaweni ependiwe ngezindlela ezimbili.

I-Convection: Ukuze ufinyelele kalula izinga lokushisa elishisayo lokuphulukisa ifilimu yokugqoka, ukugeleza komoya okusheshayo kuyadingeka, futhi ukuguqulwa kwejubane eliphezulu kutholakala ngokujikeleza umoya oshisayo esithandweni sokumisa ngesivinini somoya (i-convection ephoqelelwe).

Ukushisa okukhazimulayo: Udonga lushiselwa ngamadigri angamakhulu amaningana ngaphezu kwezinga lokushisa lokuphulukisa lefilimu yokumboza esithandweni sokumisa esiklanywe ngokukhethekile, futhi ukushisa okushisayo kudluliselwa endaweni ependiwe ngendlela efanayo nesitofu esifudumeza ngayo umzimba.

Isikhathi sokuthumela: Nov-08-2022